About Factory

Pellentesque habitant morbi tristique ore senectus et netus pellentesques Tesque habitant.

Pellentesque habitant morbi tristique ore senectus et netus pellentesques Tesque habitant.

The Chandna Mills Group has been a frequent recipient of various awards and trophies for the Export Performance by the Government of Pakistan.

Reliable

CM is a leading textile house and is engaged in diverse aspects of textile manufacturing consisting of spinning, weaving, processing, finishing and stitching

Quality means customer needs is to be satisfied. Failure to maintain an adequate quality standard can therefore be unsuccessful. But maintaining an adequate standard of quality also costs effort.

Quality is of prime importance in any aspect of business. Customers demand and expect value for money. As producers of apparel there must be a constant endeavor to produce work of good quality.

“The systems required for programming and coordinating the efforts of the various groups in an organization to maintain the requisite quality”. As such Quality Control is seen as the agent of Quality Assurance or Total Quality Control.

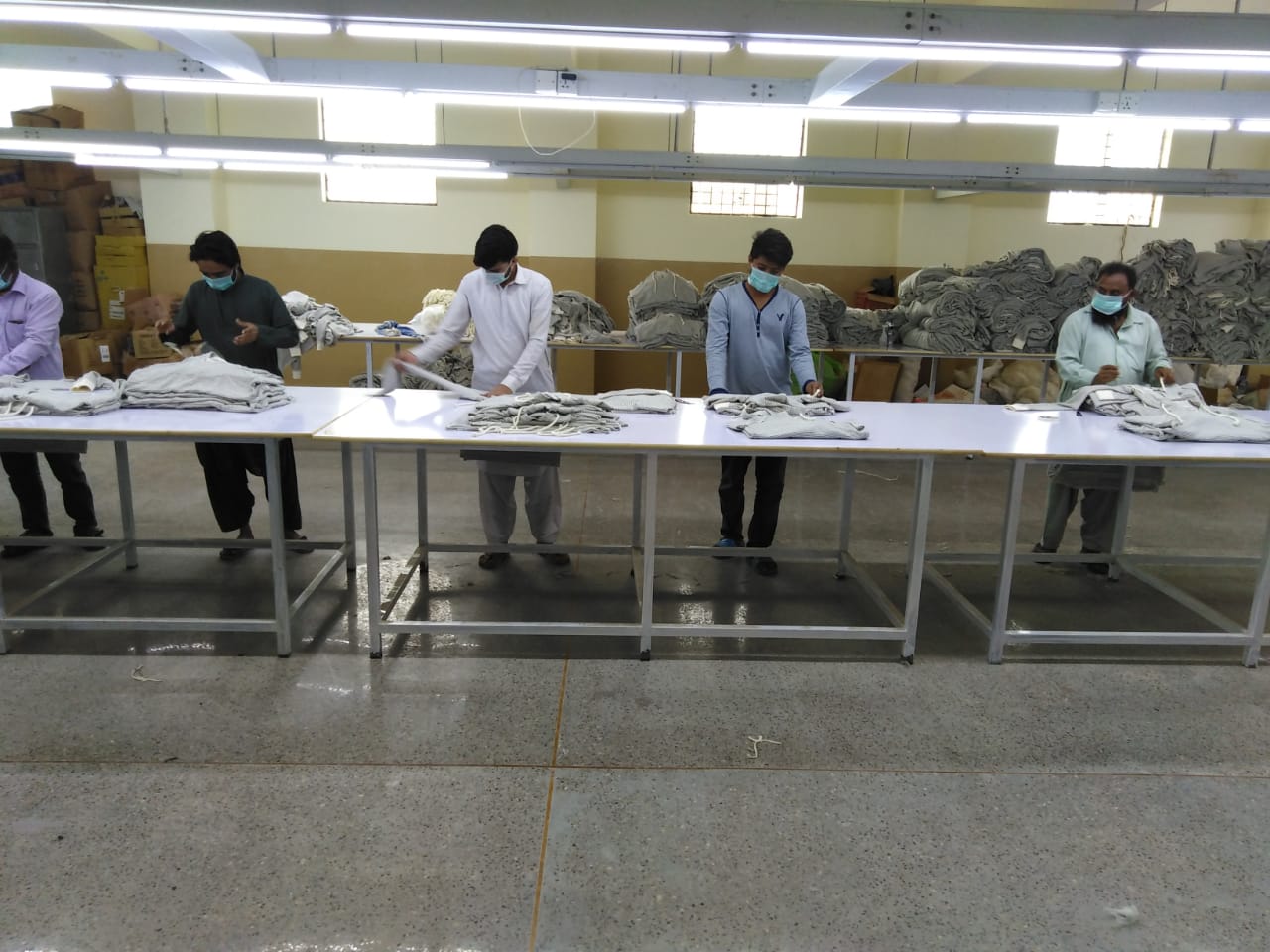

Stitching is the process whereby fabric is fashioned into a finished product by means of different sewing techniques. The stitching stage holds extreme significance to ensure that the product takes its shape according to requirements. In itself a highly specialized field, stitching requires care and precision.

We have a vast range of stitching units fully equipped with state of the art machines automatic, semi automatic, and manual. This gives us flexibility and speed to produce many types of garments simultaneously. We have the experienced and technical team in production and quality which ensure the tailoring art of stitching.

The cutting department is responsible for cutting fabrics and feeding the sewing department with cuttings. The cutting department’s capacity is planned based on the daily feeding requirement of the sewing lines. The cutting department is set up with a cutting department head, cutters, spreaders, quality checkers and helpers for sorting, ply numbering and bundling.

The cutting department gets a cut order from the production manager. According to the cutting plan, the cutting in-charge generates a fabric requirement sheet or requisition slip to the fabric store to issue fabrics.

Pressing is an important finishing process done by subjecting a cloth to heat and pressure with or without steam to remove unintended creases and to impart a flat appearance to the cloth or garments. Also, apparel pressing is done to introduce creases in the garments. In apparel industries, pressing is also called ironing. It is done by the pressing iron into the fabric, then lifting it back up to move across the fabric, then pressing it down again.

Different types of unwanted creases and crinkles are happened during making of garments. It may be forms due to the washing of garments. To remove these unwanted creases and crinkles from the garments, pressing or ironing is done.

Satisfy Clients

Repeated Clients

Permanent Clients

More Clients

KNITTING DIVISION

Pellentesque habitant morbi tristique senectus et netus pellentesque neolitics.

PRINTING DIVISION

Thank you very much for your professional services. We are impressed by your concepts and commitment to the deadlines. We look forward to working with you in the future as well…

THOR VAZ DE LEON

“we are extremely happy with the service level and the assistance given when things need to be updated. We find the Company at the cutting edge of technical solutions and the mentality have always been that there is always a solution to a problem.”

MANZER NAUMAN

Always available to answer any questions. Very knowledgeable about the services they provide. Would recommend to anyone!

Hunter Lowder

Greatest appreciation to you and your team for the outstanding job you did for us.

Bill Gates

Amazing team and effective solutions that resulted in highly rated search optimization results and catchy branding… Running our tourist and visitor guide has never been so easy!

Cheryl DeMars

I would like to describe my personal experience about Chandna Mills is only company that you can trust blindly for buying fabrics as that person having good knowledge of fabrics.

MR. YOSHINORI OKAMOTO